BLOG

Most Recent Posts

Most recently, I've been writing about organizational level change and how you improve your outcomes and key results.

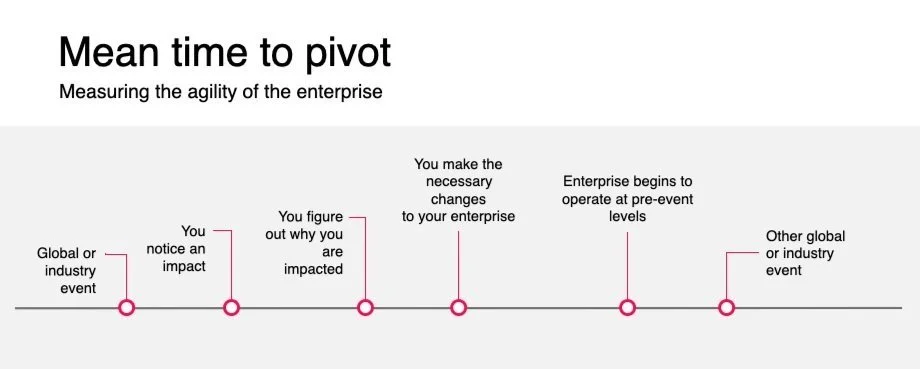

As an executive, you will be faced with the choice to do the pivot (if you can) or persevere (if you have no other choice). This will lead to a series of “bets”. You lead with a hypothesis that the things you change will allow you to operate at pre-event levels. But, how long will it actually take for you to validate your hypothesis and have a bet pay off with pre-event levels? If you run out of time to figure it out or run out of bets you can place, then you either lose your standing in the market or worse risk going out of business.

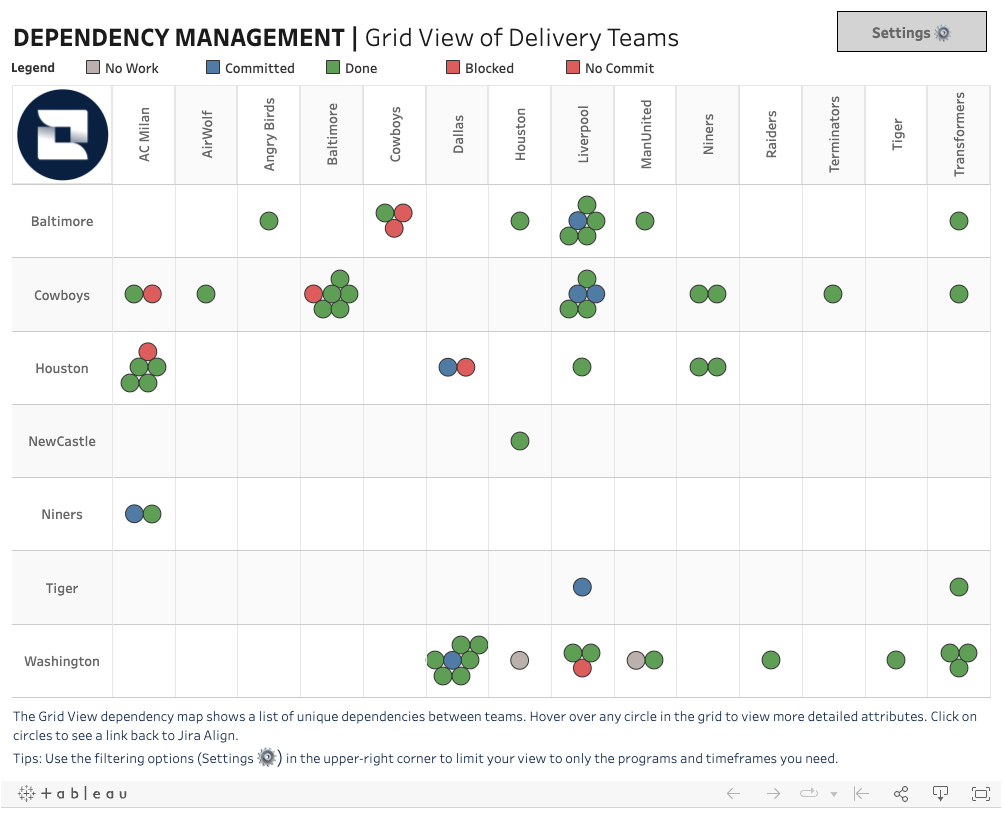

Regardless of the organization or institution, there will always be dependencies. The larger the organization, the greater chance of the existence of dependencies.

This template is available for download from Tableau Public

In the following interview (both video and audio), Dave Prior and I explore why Value Stream Management is so important, how it works, the connection to Value Stream Mapping, and how you can get started with it.

Key performance indicators (KPIs) are metrics that are used to evaluate the performance of an organization or individual. They are used to measure progress towards achieving specific goals or objectives and to determine whether an organization or individual is meeting their targets.

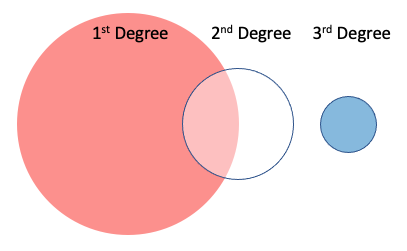

I recently noticed a lot more Facebook'y content in my LinkedIn feed. I’m assuming this is a new "feature" but I would love the ability to disable it in settings. It appears I am now seeing 3 degrees of connection engagement in my feed.

I keep getting asked, does Jira Align support Flow Metrics, as defined in the Flow Framework and SAFe? The short answer is yes. If you believe these metrics will help unlock the potential of your teams, use this community post to see working examples of Tableau reports I have created using Jira Align and Enterprise Insights.

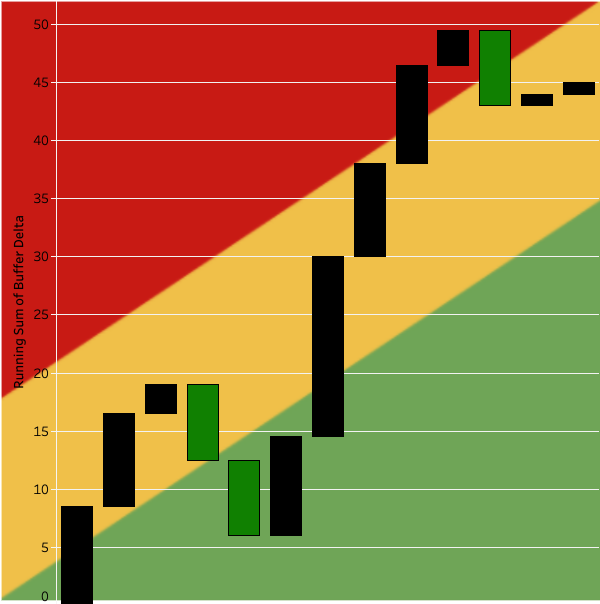

A buffer chart displays the consumption of buffer time relative to an estimated time commitment. If your boss asks you how long it will take you to complete something, you will likely add a “buffer” or pad the estimate, to increase the chance you’ll complete the work relative to your estimate.

I recently had the pleasure of doing a webinar with Rune Christensen from Scaled Agile, on the topic of Lean Portfolio Management and Metrics. Lean Portfolio Management is rapidly becoming one of those terms people want to talk about, up there with Value Stream Management. In my world, everyone seems to want to talk about metrics.

You know the overall delivery capacity of your portfolio and you make a point to balance it with demand. But when looking at what your portfolio delivered this last quarter, you know you’re coming up short… way short.

Though Atlassian (my employer) doesn’t have an annual bonus structure like the Brownie Points, we do have a mechanism to reward others and thank them for some good deed or an action that inspired us, by living Atlassian values. We call them kudos.